Tech Tuesday for 10/23 Blue Phosphorus and the Flying Dandelions

Oscar Gordon’s Tech Tuesday for 10/23

[TT1] Increased CO2 makes plants greener, says NASA. Don’t get too excited that we don’t have to worry about Climate Change, no one knows how much this mitigates things, especially given the rate of deforestation.

[TT2] U-Mich gets $2M to try and advance the development of Algae Bio-Fuels.

[TT3] A sample size of 10 is insufficient to declare that each printer has a unique infill pattern, but I could see it used to match a suspected item to a given printer (i.e. we won’t be seeing federal databases of printer infill patterns).

[TT4] 3D printing batteries to be nearly any shape (other than round or rectangular). It’s early, don’t expect this to be a thing anytime soon, but it’s a neat idea.

[TT5] Can carbon fiber store electrical energy, like in the body panels of a car? I imagine Boeing is paying attention to this and wondering if they can do away with those heavy batteries that were causing them so much trouble a few years back.

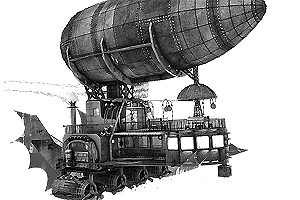

[TT6] Novel approach? Yes. Breakthrough, paradigm shifting? I won’t be holding my breath for it. Seems more niche than world changing.

[TT7] Speaking of novel flight, we didn’t really know how dandelion seeds flew. This is some pretty cool base CFD and Aero research. Now I just have to wonder how long before some startup tries to sell this as the next paradigm shift in personal air travel?

[TT8] Going to Mercury on 4 ion thrusters!

[TT9] Levitating things with acoustics is always fun.

[TT10] I am truly glad to see Sandia taking this approach toward the idea of a hydrogen infrastructure. It’s not as simple of a problem as many make it out to be.

[TT11] GE has a new jet engine for the first supersonic business jet. Honestly, business jets make sense for supersonic passenger travel. The economics are better.

[TT12] These guys just won the X-Prize for Water Abundance. Winning required being able to pull 2000 L a day from the air, using only renewable power, and at a cost of less than $0.02 / L. From my read, they didn’t meet the winning criteria, but they got closer than anyone else, so they won. And before anyone calls foul, the X-Prize sets a target that it can’t really know is reachable, so it makes sense that a winner would not always be able to hit all the targets.

[TT13] Blue Phosphorus is going to be the name of my 2D New Age band.

[TT14] OK, a booster a week, that’s ambitious. And I’m curious about how much of the booster is 3D printed. I’ll also be curious to see how long it takes them to iron out the QC wrinkles.

[TT15] “We also discovered that if a shockwave hits a number of surface pores at once, they bootstrap each other. It’s an explosive party, and they party well together.”

[TT16] Brown University thinks they have a better catalyst for fuel cells, one that lasts a lot longer.

[TT17] I think I’ve linked to something like this before, so I’m not sure if this is a new technique, or just an update of the previous, but either way, I hear progress.

TT14: A little booster: 150 kg to 500 km orbit max. Although if they’re cheap, some of us may live to see an actual Kessler Syndrome as everyone with a couple million dollars throws something into LEO.

Separately, reports have appeared over the last few days that Intel is scrapping its 10nm fabrication process, at least for the time being. Rumors are that they have been unable to get the yields up to the level where the they can make money. I have long said Rock’s Law — the cost of a leading-edge fab doubles every four years — would be a limit sooner than the more famous Moore’s Law. A number of the Far East foundry companies stopped at 20nm because of the costs to go smaller. I have a bet that 10nm is the bottom for everyone except companies backed by national governments (eg TSMC (Taiwan) and Samsung (South Korea)), and even they won’t ever go below 7nm.Report

150kg is a whole bunch of cubesats. Governments are going to have to start requiring that what goes up must be able to reliably bring itself down.

So what is the reason for the cost increase for IC fab? And if we can’t get below 10nm, what does that mean for IC (besides the obvious of, we can’t make smaller devices).Report

Technical note: the X-nm designations have lost a great deal of their meaning except relative to each other within a manufacturer’s fab family. 10nm means “twice as many transistors per square mm as 14nm”. Some of that may be due to smaller features; some of it may be due to stuff like finFETs where transistor structure is 3D rather than 2D. Samsung announced a 7nm process yesterday. In terms of transistor density, it’s about the same as Intel’s 10nm process. In a year or so we’ll know whether they can find enough customers and get high enough yields to make money at it.

IC fab is expensive because it sits at the top of a huge pyramid of engineering tech in many fields. Consider just physical positioning: for some 10nm features, macro-scale objects have to be positioned relative to each other with sub-nm accuracy in three dimensions. On the order of a hundred times to get one chip, if it’s a complex one. In some cases, to overcome the limits of the optics, moving macro-scale objects are positioned with sub-nm accuracy relative to one another.

If it’s not profitable to go below 10nm? More parallelism, more special-purpose processors. NVidia’s latest offerings are done using someone’s 12nm process. Big dies; pushing 20B transistors; special processors for ray-tracing; special processors for neural networks; thousands of shader cores. More and more supercomputers are being built from GPUs, not CPUs.Report

TT5: Potential is there still a bit pie in the sky. ARL has actually been working on this for over a decade.

TT6: I don’t know that it’ll get anywhere, but the CFD is cool and I love the images – very scifiReport

It is some pretty cool research. I should see what I can pull from the public released stuff at work and do a TT dedicated to aero research.Report

Notable passing: Raye Jean MontagueReport

A true trailblazer. Much like the women in Hidden Figures.

Fair winds and following seas, Ms. Montague.Report